The goal of predictive maintenance is to avoid downtime by using sensor data to predict when maintenance is necessary. What if the machine could indicate when one of its parts was about to fail? What if the machine could even tell you which part needed to be replaced? Planned maintenance could be significantly reduced and unplanned downtime would be reduced.

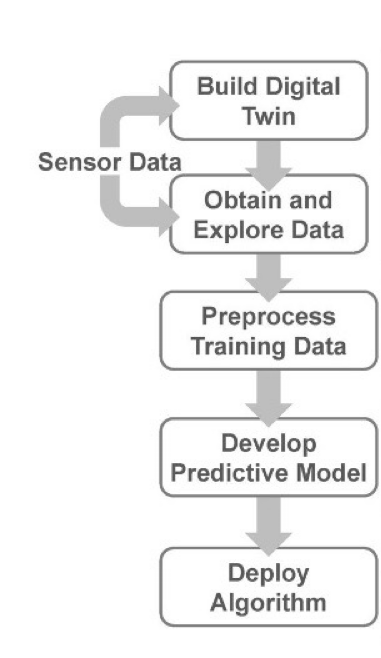

At the heart of developing any predictive maintenance algorithm is sensor data, which can be used to train a classification algorithm for fault detection. Meaningful features are extracted from this data in a preprocessing step and used to train a machine learning algorithm for predictive maintenance. However, it is not always possible to acquire data from physical equipment in the field under typical fault conditions. A solution to this challenge is to create a digital twin of the equipment and generate sensor data for various fault conditions through simulation. This approach enables engineers to generate all sensor data needed for a predictive maintenance workflow, including tests with all possible fault combinations and faults of varying severity.

A digital twin is a virtual representation of a physical object or system synchronized at a specified frequency and fidelity and is updated from real-time data, and uses simulation, machine learning to represent more accurately the current and future state of their physical object.

In lots of applications, combining physics-based models with even limited data can improve the accuracy of the digital twin model. This is where neural networks models can be more accurate. Predictive analytics is the key to prescriptive analytics in identifying failures and proactively offering corrective action. deepdatamind.org offers the best possible solutions to your specific problems to improve yield, reduce test time, and improve efficiency in high technology and manufacturing operation.